Light Installation

Typhoon Installation

- Choose a location on the transom 6 to 12 inches beneath the waterline. Mounting surfaces should be flat, clean, dry, and free of any existing hardware or holes. Check inside of the hull for wiring or obstructions.

- Before mounting, ensure that the light will not interfere with the operation of engines, trim tabs, rudders, etc. Clean the gelcoat or remove any bottom paint from the gelcoat surface. Mark the light center and cut the appropriate hole for your housing type. Refer to the instructions for the recommended hole saw size.

- Spread a generous bead of sealant (3M4200 or equivalent) around the inside surface of the light bezel.

- Feed the light housing through the hole and orientate using the logo on the reflector. Fasten in place with tape.

- On the inside of the hull, apply a generous bead of sealant (M4200 or equivalent) to one surface of the stainless steel washer and feed the washer over the threads of the light with the sealant side making contact with the hull.

- Thread the Compression Nut Retaining Ring onto the light housing threads and fasten until approximately one inch from the steel washer.

- Install the three supplied retaining bolts to the Compression Nut Ring until they make contact with the steel washer surface (hand-tight). Tighten with a socket wrench until sealant extrudes from behind the washer. DO NOT over-tighten.

- Install the Bonding Lug with supplied nut and both, and clean off any access sealant for the front and rear of the light.

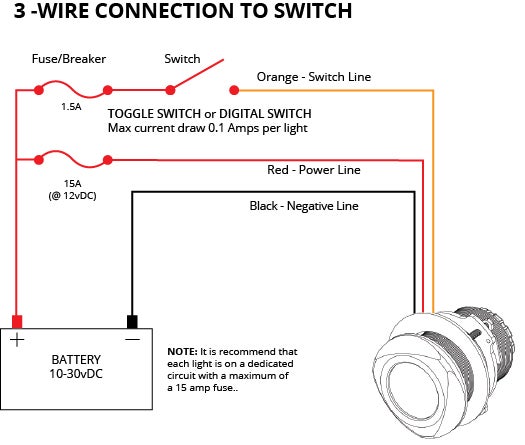

3-Wire to Switch Wiring

Wiring recommendations: Use ABYC standards to calculate wire size based on the length of the run. If installed as a 3-Wire configuration, the orange wire carries less than 1A of power, and typically, an 18AWG wire can be used. The orange wire of the Typhoon light is the light's internal relay and sends commands from the Poco digital lighting control system (if installed).

TIP: To minimize electrical noise and interference, running the positive (red) power and ground (black) return together for as much of the wire run as possible, ideally inside a jacketed cable, is recommended. Avoid loops and coils of the wiring.

- Ensure that the circuit you are connecting to has no power. You should turn off your house battery and test to ensure the circuit is not energized by using a multimeter before continuing.

- Run a marine grade 2 or 3 conductor wire from the light to your switch. On a 12vDC system, your switch and fuse should be rated for 15A maximum (7.5A @ 24vDC). View wire gauge reference chart HERE.

- Connect the wires from the light to the new wire run and follow ABYC standards. Ensure that the wires are crimped correctly, and use a heat gun on the heat shrink of the butt splice connectors.

- Verify the switch is a Single Pole Single Throw (SPST) switch; it has the appropriate Amp rating and is connected to house power through a properly sized fuse. Recommended switch size for a 3-wire installation is 1A (minimum) switch.

- Turn on house power and test the new Typhoon underwater light.

Light Operation

How to Select Color/Mode

STEP 1: First, turn the light on, it will begin in a low power mode, and over the course of 4 seconds, the light will ramp up to full brightness of 10,000 lumens.

STEP 2: After 4 seconds, the light will be at full intensity. With a brief toggle of the power switch, turn the light off/on once. This will move the light into color cycle mode. The light will now cycle through the complete color spectrum for 15 seconds, followed by a 3-minute color cycle.

STEP 3: When the light reaches the desired color, toggle the power switch off/on one more time to lock on the color. Turning the light off for 4 seconds will reset the color cycle to the beginning.

TTP (Timed Toggle Protocol)

For more information on the built-in TTP technology, check out the video.